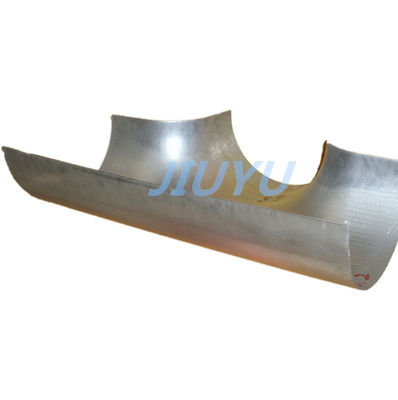

Model 100-100 T-Pipe in Fitting Deep Drawn Metal Stamping in Building

Metal Duct Connectors from Equipment of Hydraulic Press. Firstly, the tube blank is placed in the lower die, then the upper die is pressed down, and then the shaft heads at both ends are pressed against the end of the tube blank. Then, the high-pressure liquid is introduced into the central hole of the shaft head, and the required parts are obtained by bulging under the joint action of the high-pressure liquid and axial compression force. The bulging method of axial compression and high pressure liquid is adopted. Bulging belongs to the category of stamping.

Product Description:

![]()

Product Display:

![]()

![]()

Workshop Display:

![]()

Product Inspection:

![]()

Packaging:

![]()

Why choose us?

Operating Since 2006

We started activity on the market in the year 2006 year in which Customization all kinds of metal stamping parts.

Benefit from Our Advantages

*Reduce your purchase cost with keep in long time cooperate--

We keep in long time cooperate with our cooperate partner. We need to work as customer-centric from price, delivery time and market need. We strive to be a preferred and trusted supplier by developing an in-depth understand.

*Building such diverse customer network with supplier chain activity---

We build our clients a diverse range of industries: Marine, Automotive, Electronics and Electrical, Machinery, Industry….requires the ability to offer competitive pricing, better solutions, extraordinary technology expertise and industrial. We continuously strive to improve ourselves, to source highest quality products at the lowest cost, and to ensure on-time delivery to our customers.

*Customized - Design your product--

We meet your design needs with your drawings or samples. There is experienced technology design tooling as your drawings. We can work with PDF, 3D, CAD, CAXA, Solidwords…

Complete Capability

We offer our customers complete capability - from die design and manufacture to long run production, assembly, finishing, and plating if required.

Value-added services

Value-added services such as assembly, machining, welding, Injection plastic parts and various surface treatments and coatings to reduce your supply chain.

Through the use of computers we are able to design and fabricate either single stampings or progressive dies to insure that your parts are made to the highest standard of quality on a cost effective basis.